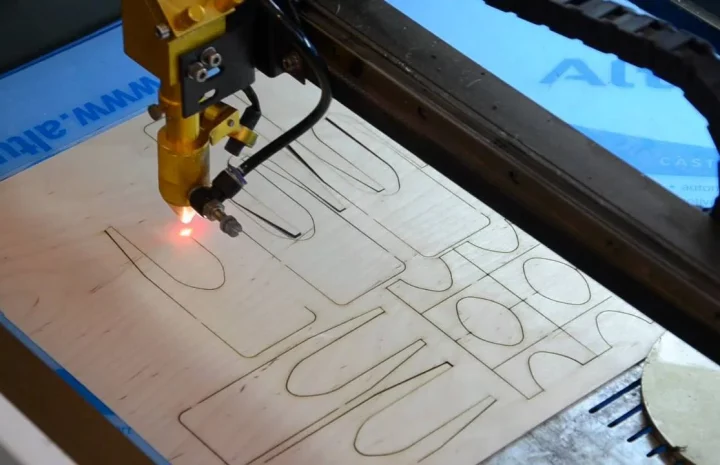

Laser can be utilized to cut a wide assortment of materials. With a Mica Laser Cutting machine, paper and plastic can be effortlessly cut much. Indeed, even pressed wood up to 1 thick can be cut by this machine. Cutting metal sheets also can be utilized. Ordinarily force of the laser is tweaked to choose different levels cutting. Little mirrors are utilized to direct light from the laser to a specific area on the material. The foundation of the cutting region is produced using a honeycomb material to allow the laser to light go through. This must be supplanted intermittently. Mica Laser Cutting machines are unmistakable from conventional mechanical cutters. Since the laser never connects with material and there is less an open door for the material to become polluted. Mica Laser Cutting machines likewise cut material with higher accuracy than that of mechanical means. Besides its benefits over customary mechanical cutting, Mica Laser Cutting is a tranquil cycle. Security is likewise significant and, subsequently, most laser machines are completely encased to forestall mishaps.

The most well-known kind of laser shaper that anyone could hope to find in industry today is the CO2 laser. It offers benefits over different kinds of lasers for reducing in expense, effectiveness and power accessible and has turned into the business cat laser mica. Mica Laser Cutting with a CO2 lasers finish is brilliant in contrast with cycles, for example, oxy or plasma. Right utilization of effective spouts, feed speeds, beat settings and gas tensions can create great square cuts with a smooth completion. For most applications insignificant post completing is required. In any case, CO2 Mica Laser Cutting cannot recreate a machined finish. Parts normally have an intensity impacted zone; however this is little in contrast with the more conventional cycles. Heat contortion is extremely negligible and this is one of the vital benefits of the cycle.

CO2 laser framework can be utilized anyplace the more regular cycles, for example, oxy and plasma cutting are utilized. Yet, a CO2 laser shaper enjoys the benefit in having the option to cut a more extensive assortment of materials like plastics and wood. CO2 lasers can be mounted on different movement frameworks from little work area units for little work, to immense gantry frameworks for cutting huge plates, to robot arms for 3D cutting. Only a couple of the wide assortment of uses for CO2 Mica Laser Cutting are profiling of steel shapes, cutting or boring of openings in steel parts, cutting of slight sheet metals, cutting of plastic signs and veils, cutting of profiles in wood and cutting of textures and plastic movies.